Group website:

Other company websites:

Choose website

Full Body X-ray Scanners – 6 Critical Aspects to Consider Before Buying

Full Body X-ray Scanners – 6 Critical Aspects to Consider Before Buying

Full and Partial Body scanners are complex systems that combine multiple technologies and are part of a wider overall security ecosystem. Selecting the right x-ray scanner requires careful consideration of the scanner’s operational environment, what items will be scanned, and what threats are expected. This article explores six critical factors that key decision-makers and security professionals should consider before purchasing equipment.

Full and Partial Body scanners are complex systems that combine multiple technologies and are part of a wider overall security ecosystem. Selecting the right x-ray scanner requires careful consideration of the scanner’s operational environment, what items will be scanned, and what threats are expected. This article explores six critical factors that key decision-makers and security professionals should consider before purchasing equipment.

1. Scanning Technique & Modes

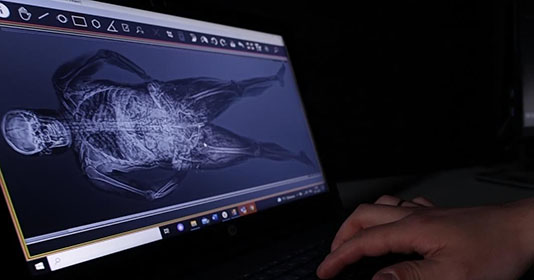

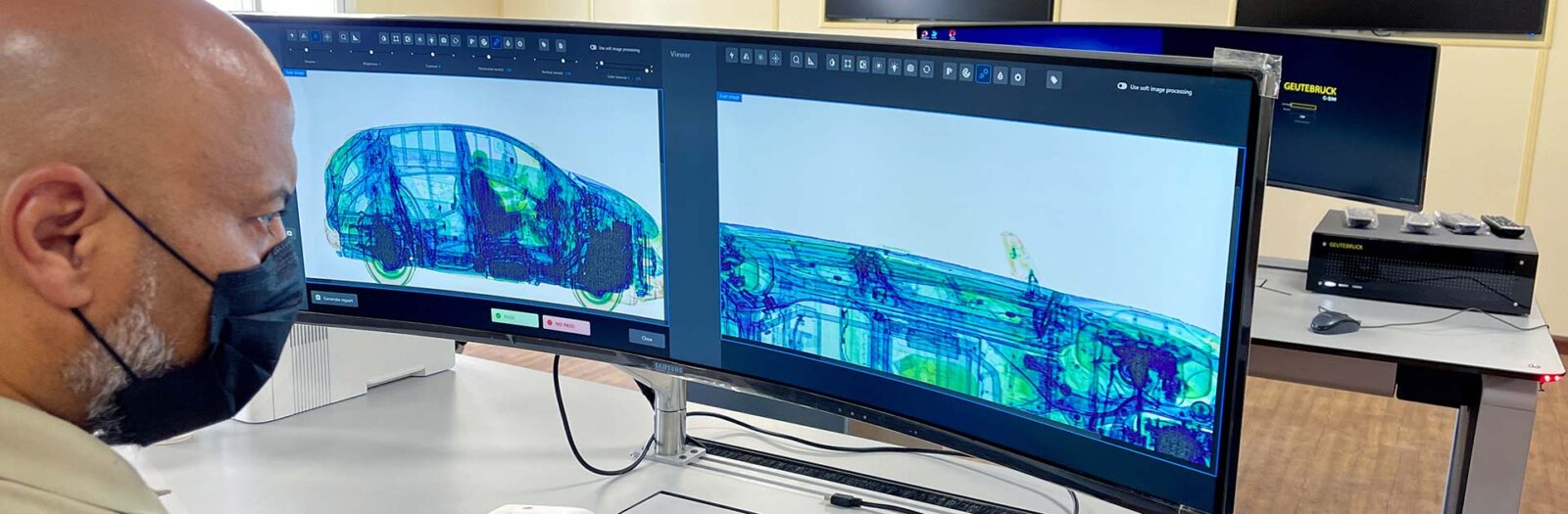

Full-body x-ray scanners are currently offered with either a stationary scanning design or one in which the person moves through the x-ray beam on a platform or conveyor belt. Additionally, these scanners may feature multiple energy levels and even two imaging capabilities.

2. Automatic Detection Algorithms

The future is now. Sophisticated detection algorithms that leverage Artificial Intelligence (AI) are becoming more prevalent across a wide range of x-ray imaging security solutions. Early versions focused on explosive detection, specifically for the aviation industry, but now the software is advanced enough to detect guns, knives, bullets, and IEDs inside baggage, purses, and backpacks with a range of mixed contents. The evolution of the principles used to create such automatic detection software has led to the creation of products like DruGuard4®, the first-of-its-kind full-body detection software that focuses on internally concealed narcotics. In addition to placing a box around the suspect area of narcotics, DruGuard will also alert the operator as to the probability of detection based on size, density, quantity, and shape.

AI is a powerful tool that allows engineers to enhance detection algorithms to improve accuracy and provide operators with smart assistance in reviewing X-ray images like never before. Supervisors value the level of accountability the software brings to the screening process. Enhanced reporting capabilities allow Administrators and Supervisors to access reports on operator performance and trends, thus providing the opportunity for them to make adjustments through training, assignment, and support.

3. Image Quality

Image quality is critical to all x-ray scanner performance. X-ray scanners are only as effective as the quality of their imaging. The inspection process, despite a myriad of image manipulation functions and automation programs, still relies upon the ability of an analyst to review the image and identify threats. If an x-ray manufacturer produces low-quality images that are blurred or pixelated, it will be challenging, if not impossible, for analysts to screen effectively and identify threats and contraband. Image quality can be broadly determined from the following attributes:

4. Service

Service quality is important to consider for maintenance of an x-ray scanner. Scanning machines are complex, often require difficult-to-acquire components for repair, and are necessary as part of a larger security regime. The quality of a service contract is determined by the following qualities:

5. Training

A service organization should have a comprehensive training program for operators of the systems, inspection personnel, and local service technicians. Central service techs who work at the manufacturer’s headquarters might be far remote from the scanner’s installation site, so the ability to train local technicians ensures timely repairs.

6. Total Cost of Ownership & Measurable Results

The final factor may seem obvious, but it encompasses multiple aspects of acquiring, running, and maintaining an x-ray system. Ensuring maximum product value with minimal lifetime costs requires a holistic review of the items below:

A scanner that is less expensive upfront but fails frequently, has slow service support, and significant downtime or requires costly generator replacements, has nowhere near the value and low total cost of ownership of an effective, well-maintained scanner. It is critical to evaluate build quality, robustness, and design to determine exactly which x-ray scanner is best for your security mission.

Headquartered in Conroe, Texas, LINEV Systems has been the leader in full body scanning systems since 2006. LINEV Systems is a manufacturer with nearly 20 years of experience and has ISO-certified manufacturing to the highest American quality standards.

Looking to purchase a full body X-ray screening system? Have questions? Email our experts at sales@linevsystems.com or call us directly at (936) 588-2064 for more information.

1. Scanning Technique & Modes

Full-body x-ray scanners are currently offered with either a stationary scanning design or one in which the person moves through the x-ray beam on a platform or conveyor belt. Additionally, these scanners may feature multiple energy levels and even two imaging capabilities.

| Stationary Scanners Often offer the highest level of convenience and in the case of CLEARPASS are ADA compliant, with the ability to scan a person in a wheelchair. |

| Moving Platform / Conveyor Belt These systems can control the noise introduced to the images by having the x-ray generator and detector remain stationary while moving the subject through the x-ray beam. |

| Single vs. Dual View Scanners Single View Scanners offer a full body image head to toe, while a Dual View Scanner will offer that same head-to-toe image but also include a High-Definition Torso image. The torso is the primary location of contraband moving in and throughout facilities, so this gives the operator the best imaging of this high-impact location. The SMART DV system can run the generators independently, which gives the operator the highest number of options at 9 different scanning levels. |

| Multiple Energy Modes – Low, Medium, High, and Beyond This controls the amount of x-rays used on each scan, allowing the operator to set a level depending on the subject being scanned. |

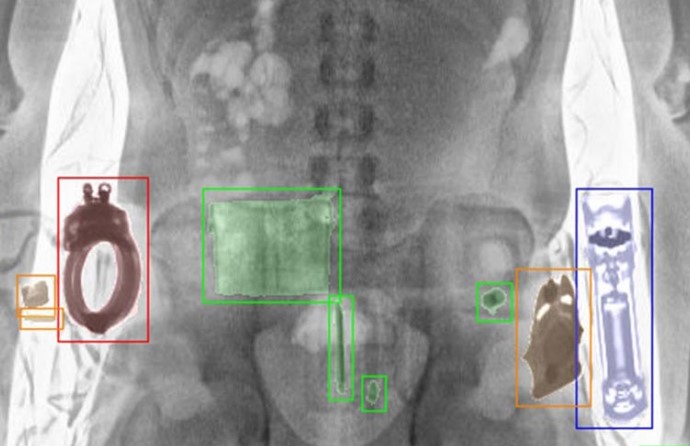

The future is now. Sophisticated detection algorithms that leverage Artificial Intelligence (AI) are becoming more prevalent across a wide range of x-ray imaging security solutions. Early versions focused on explosive detection, specifically for the aviation industry, but now the software is advanced enough to detect guns, knives, bullets, and IEDs inside baggage, purses, and backpacks with a range of mixed contents. The evolution of the principles used to create such automatic detection software has led to the creation of products like DruGuard4®, the first-of-its-kind full-body detection software that focuses on internally concealed narcotics. In addition to placing a box around the suspect area of narcotics, DruGuard will also alert the operator as to the probability of detection based on size, density, quantity, and shape.

| A-EYE® is another platform that not only identifies objects on or inside the human body, but also classifies them into 4 key groups: Clothing and Accessories = Green Electronics = Blue Threats = Red Other Foreign Objects = Orange |  |

AI is a powerful tool that allows engineers to enhance detection algorithms to improve accuracy and provide operators with smart assistance in reviewing X-ray images like never before. Supervisors value the level of accountability the software brings to the screening process. Enhanced reporting capabilities allow Administrators and Supervisors to access reports on operator performance and trends, thus providing the opportunity for them to make adjustments through training, assignment, and support.

3. Image Quality

Image quality is critical to all x-ray scanner performance. X-ray scanners are only as effective as the quality of their imaging. The inspection process, despite a myriad of image manipulation functions and automation programs, still relies upon the ability of an analyst to review the image and identify threats. If an x-ray manufacturer produces low-quality images that are blurred or pixelated, it will be challenging, if not impossible, for analysts to screen effectively and identify threats and contraband. Image quality can be broadly determined from the following attributes:

| Contrast The contrast in an image is the ability to differentiate light and dark areas which, in the case of x-ray scanners, means the ability to differentiate two areas of close, but not identical, density. |

| Spatial Resolution Spatial resolution refers to the ability of a system to separate similar items that are adjacent. If two items of similar density and material are very close to each other, a poorly performing machine may tend to combine the distinct items into a single detail in the scanned image. Spatial resolution is often stated as the minimum distance between two wires suspended in air at which a system can differentiate the wires in an image. Thus, a lower spatial resolution is more desirable. |

| Noise Noise is a general term to refer to undesired photons that are detected in the image. High noise can make an image appear grainy or blurry. Although it’s impossible to remove all noise from an image completely, reducing noise is key to good image quality. |

| Sharpness Sharpness is the edge resolution in an image. High sharpness means crisp edges that are easily defined, whereas low sharpness indicates that the edges of details are blurry and may blend. |

4. Service

Service quality is important to consider for maintenance of an x-ray scanner. Scanning machines are complex, often require difficult-to-acquire components for repair, and are necessary as part of a larger security regime. The quality of a service contract is determined by the following qualities:

| Mean Time Between Failures (MTBF) The MTBF refers to the expected time between major failures that would shut down operation of the system. This will be based on past installations and field testing of the system. A higher MTBF means that the machine will fail less over a given time period.” |

| Mean Time to Repair (MTTR) The MTTR refers to the expected time between the failure of a critical system component and the completion of repairs by a repair technician. This includes response period, travel time of the technician, diagnostic time, sourcing of parts, and time for repairs. A lower MTTR means that repairs are completed faster, and the machine returns to operation earlier.” |

| Spare Parts Availability A good service organization will maintain spare parts inventories that are readily available for repairs anywhere that a system is installed. Many critical components of an x-ray scanner have long lead times from the manufacturers, so the x-ray scanner manufacturer should maintain an inventory of these components so repairs can be completed quickly. |

| Remote Service Capabilities Remote service allows a service organization to diagnose problems remotely by communication with the customer, and perhaps guide customer personnel through basic repairs if possible. A service organization should maintain remote service capabilities to ensure timely and quality repairs. |

| Preventative Maintenance A good preventative maintenance schedule ensures that the machine does not break down due to neglect or easily preventable problems. Service organizations should have a regular preventative maintenance schedule and should ensure that such repairs are completed with minimal involvement of the customer. |

5. Training

A service organization should have a comprehensive training program for operators of the systems, inspection personnel, and local service technicians. Central service techs who work at the manufacturer’s headquarters might be far remote from the scanner’s installation site, so the ability to train local technicians ensures timely repairs.

6. Total Cost of Ownership & Measurable Results

The final factor may seem obvious, but it encompasses multiple aspects of acquiring, running, and maintaining an x-ray system. Ensuring maximum product value with minimal lifetime costs requires a holistic review of the items below:

| | Purchase Price |

| | Personnel Requirements |

| | Training Costs |

| | Product Reliability |

| | Service Warranty |

A scanner that is less expensive upfront but fails frequently, has slow service support, and significant downtime or requires costly generator replacements, has nowhere near the value and low total cost of ownership of an effective, well-maintained scanner. It is critical to evaluate build quality, robustness, and design to determine exactly which x-ray scanner is best for your security mission.

LINEV Systems US is the Manufacturer of Choice

Headquartered in Conroe, Texas, LINEV Systems has been the leader in full body scanning systems since 2006. LINEV Systems is a manufacturer with nearly 20 years of experience and has ISO-certified manufacturing to the highest American quality standards.

Looking to purchase a full body X-ray screening system? Have questions? Email our experts at sales@linevsystems.com or call us directly at (936) 588-2064 for more information.