Group website:

Other company websites:

Choose website

Electron Spin Resonance (ESR) Systems – Book a Product Specialist

Electron Spin Resonance (ESR) Systems – Book a Product Specialist

Electron Paramagnetic Resonance (EPR), more commonly referred to as Electron Spin Resonance (ESR), has become an indispensable asset to food chemistry experts and researchers.

Book a complementary call with our ESR product specialist to discuss the specific requirements of the ESR system you are looking for by calling (936) 588-2064 or 1 (844) 989-6789

Electron Spin Resonance (ESR)*, has become an indispensable asset to food chemistry experts and researchers. By detecting paramagnetic species–molecules or atoms with unpaired electrons–this cutting-edge analytical technique provides precise, sensitive insights into quality, safety, and authenticity of food products. As food safety regulations tighten further and consumer expectations increase exponentially, EPR systems have become essential tools for food manufacturers, processors, researchers alike; its applications span across numerous areas of food analysis with real world data showing its success at improving product quality while guaranteeing safety while decreasing waste production.(*) Also referred to as Electron Paramagnetic Resonance (EPR).

Food quality and safety cannot be overemphasized; foodborne illnesses pose a substantial public health threat each year, resulting in millions of hospitalizations and thousands of deaths worldwide. Their economic repercussions, alongside product recalls due to safety failures, can be immense; consumers demand both transparency and safety from companies while regulators set stringent regulations to meet health requirements; against this background EPR spectroscopy provides a robust solution with its unparalleled level of precision in product analysis. EPR spectroscopy works by measuring the magnetic properties of paramagnetic species that contain unpaired electrons. This technique relies on their interaction with an external magnetic field to absorb microwave radiation; then this signal can be analyzed to gain information on nature and quantity of paramagnetic molecules present in samples; this allows researchers and manufacturers to examine complex biochemical processes, assess product degradation rates, as well as compare various production and preservation techniques used. In food chemistry this allows for studying complex biochemical processes as well as studying production/preservation practices which allows researchers/manufacturers gain insights into nature/quantity/nature and quantity present within their samples allowing researchers and manufacturers alike gain detailed knowledge regarding nature/quantity/quantity present within samples which allows researchers/manufactures analyze signals received. This allows researchers/manufacturers analyze signals received to analyze signals obtained to provide detailed information regarding nature/quantity/quantity present thereby providing detailed knowledge about nature/quantity present within samples in food chemistry research applications such as investigating complex biochemical processes/product degradation assessments/verifying their effects of various production/preservation processes/methods/properties of product degradation processes used, and ultimately evaluate effects from production/preservation techniques used.

EPR (ESR) spectrometer for food chemistry by LINEV Systems

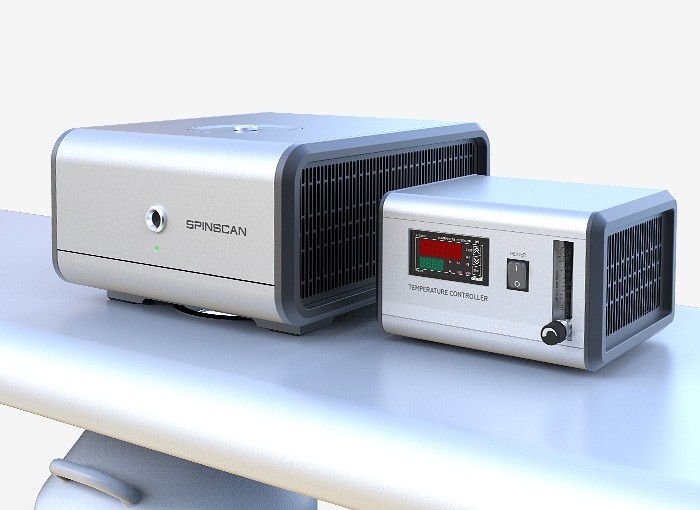

LV Analytical SPINSCAN

LV Analytical SPINSCANSPINSCAN · Benchtop X-band EPR spectrometer

Last generation ESR spectrometer with small footprint and advanced capabilities providing outstanding performance that meets the needs of scientific and industrial laboratories.

LV Analytical Catalyst studying system

LV Analytical Catalyst studying systemTemperature Controller package

Automatic temperature control system is external system to control the temperature in the sample area of EPR spectrometer in the range from -170 to +200 С. Software interface for temperature controller is integrated into main software package e-Spinoza and EPR / ESR data can be collected at elevated temperature.

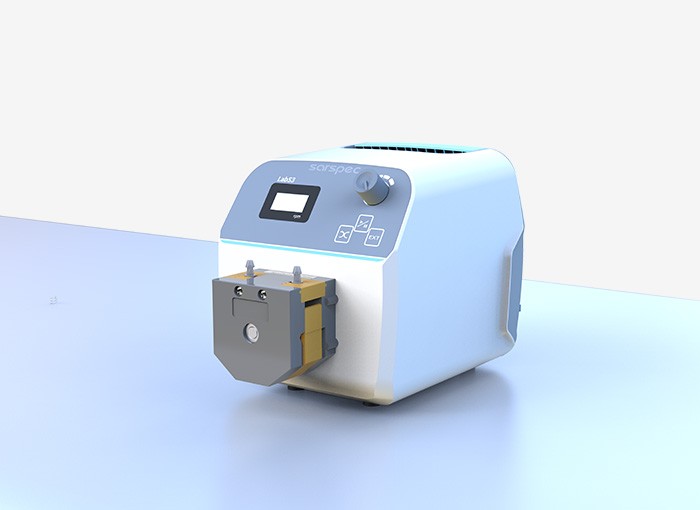

LV Analytical Accessories Continuous Flow System

LV Analytical Accessories Continuous Flow SystemContinuous Flow System

LV Analytical Accessories Photochemistry kit

LV Analytical Accessories Photochemistry kitPhotochemistry set

The access for sample irradiation in the resonator is available. Photochemistry kit is intended for identification and study of free radicals, ion-radicals and triplet-state molecules generated during photochemical processes. PhC kit includes UV – VIS light source, SMA connector and fiber optic probe.

Food Spoilage and Oxidation

One of the major challenges facing the food industry today is spoilage due to oxidation. Lipid oxidation occurs when oxygen interacts with fats found in food, leading to rancidity, off-flavors, and nutritional losses; particularly concerning in high-fat products like meat, dairy products and processed snacks. EPR spectroscopy allows accurate detection and measurement of free radicals and reactive oxygen species (ROS) involved in this oxidation process – using EPR technology allows accurate detection and measurement. EPR systems ability to monitor real-time lipid oxidation are providing invaluable insights into food product shelf life and stability. For instance, studies using EPR have illustrated how antioxidant additives like tocopherols (vitamin E) interact with free radicals to reduce oxidative stress and extend shelf life of oils and fat products. Food companies that utilize EPR systems can optimize their preservation methods while decreasing artificial preservative usage.EPR Spectroscopy for Ensuring Safety EPR spectroscopy can also help ensure food safety by identifying additives and contaminants found in products, as well as potential toxins that might pose health risks to consumers. Many food products contain antioxidants, preservatives, colorants and preservatives designed to enhance appearance, flavor or shelf life – yet excessive or uncontrolled use of such additives poses health risks that threaten consumer wellbeing. Heavy metal contaminants might even sneak in through processing without our knowledge, creating serious threats to consumer health that threaten our own wellbeing. EPR spectroscopy offers a highly sensitive way of detecting contaminants in food samples. Trace amounts of heavy metals such as cadmium or lead can be identified using their interaction with unpaired electrons, giving companies time to take corrective actions before their products reach consumers. Furthermore, this technique can also be used to monitor antioxidant concentration and ensure compliance with safety standards while upholding product authenticity.

Verifying Food Irradiation Food irradiation is a widely utilized process used to ensure food safety by eliminating harmful microorganisms, insects and parasites from products. While recognized as safe process, verifying whether products have been irradiated remains an ongoing challenge for regulatory bodies and consumers alike. EPR spectroscopy offers a solution by detecting free radicals formed as a result of radiation treatment. EPR technology can accurately detect whether food products like spices, fruits, and meats have undergone irradiation. Due to its nondestructive nature and ability for repeated testing without damage to the sample, this non-destructive testing technique makes EPR an ideal way to ensure food safety verification for companies using EPR systems for this purpose – providing regulatory authorities with assurances that their products adhere to safety standards without compromising quality standards.

Analyzing the Effects of Food Processing

Food chemists study how processing affects nutritional value and product quality as part of food chemistry research. Heating, freezing, and pasteurization processes – essential in prolonging shelf life and assuring food safety – can alter chemical structure and composition of foods – EPR spectroscopy allows researchers to examine these changes at an molecular level to gain more insight. Milk products using EPR can show how pasteurization and homogenization alter the structure of its fats and proteins, while free radical formation changes during freezing can alter texture and taste significantly. With these insights at their disposal, food manufacturers can fine-tune their processes for maximum quality and nutritional value in their products.EPR spectroscopy’s real world applications in food chemistry are many, supported by scientific evidence. One such application was highlighted in an experiment conducted by the European Food Research and Technology Journal to monitor oxidative stability of sunflower oil; EPR could detect even subtle changes to its oxidative state allowing researchers to gauge effectiveness of different antioxidants used to extend shelf life, which are directly applicable for companies looking to improve both product quality and longevity.

Why Businesses Should Invest in EPR Systems

With increased pressure from regulators around the globe to deliver high-quality, safe, and authentic food products, EPR spectroscopy tools such as EPR have never been more essential. Companies who choose to invest in these cutting-edge systems position themselves at the forefront of food science; using cutting-edge technology to meet regulatory requirements, enhance product quality and gain a competitive edge in the marketplace. EPR systems are more than a compliance solution; they’re an enabler of innovation. EPR can monitor spoilage, detect contaminants, verify irradiation and assess processing effects to create more precise, efficient, sustainable food production practices that reduce waste while optimizing resource use resulting in safer products being sold to consumers.At LINEV Systems, we specialize in offering innovative EPR solutions tailored to the food industry’s specific requirements. Our product specialists collaborate closely with businesses to understand their challenges and develop customized solutions to drive value and innovation. Whether your goal is improving shelf life, increasing safety protocols or deepening knowledge of food processing, EPR systems provide the scientific basis you need for success.